Turbochargers are one of the most important innovations in modern automotive engineering, playing a critical role in enhancing the performance and efficiency of internal combustion engines. These components are found in a wide range of vehicles, from performance cars to trucks, and even in industrial machinery. Despite their widespread use, many people remain unfamiliar with the underlying science behind turbochargers and how they contribute to the power and efficiency of a vehicle. In this blog, we will explore the inner workings of turbochargers, how they work, and why they are crucial to modern engines.

At its core, a turbocharger is a device that forces more air into the engine’s combustion chamber, allowing the engine to burn more fuel and produce more power without significantly increasing engine size. This is achieved by utilizing the exhaust gases produced by the engine itself. By harnessing this otherwise wasted energy, a turbocharger enables an engine to produce more horsepower, which translates to better acceleration, improved towing capabilities, and enhanced fuel efficiency.

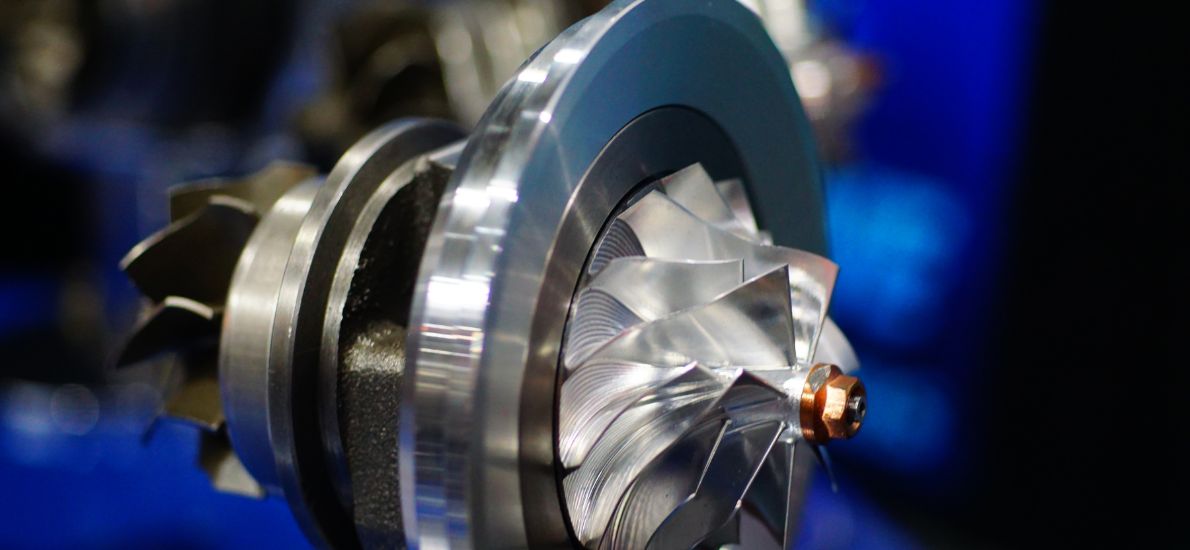

A turbocharger consists of two main components: the turbine and the compressor. The turbine is powered by the engine’s exhaust gases, while the compressor is responsible for drawing in and compressing ambient air before it enters the engine’s intake. These two components are connected by a shaft, allowing them to rotate together. As exhaust gases pass through the turbine, they cause it to spin, which in turn drives the compressor. The compressor then forces more air into the engine, enabling it to burn more fuel and produce additional power.

The fundamental operation of a turbocharger relies on the principles of thermodynamics and fluid dynamics. Exhaust gases produced by the engine are under high pressure and high temperature, which makes them an ideal source of energy to drive the turbine. As the exhaust gases exit the engine, they flow through the turbocharger’s turbine, causing it to spin at incredibly high speeds—often reaching up to 100,000 revolutions per minute (RPM). This rapid rotation of the turbine is what powers the compressor.

The compressor’s role is to increase the volume of air entering the engine. Air, being a mixture of gases, has a specific density at a given temperature and pressure. By compressing the air before it enters the combustion chamber, the turbocharger increases the air’s density, allowing more oxygen to enter the cylinder. This is critical because more oxygen means more fuel can be burned, leading to a greater explosion in the combustion chamber, and consequently, more power output.

As the compressed air enters the engine’s intake system, it is mixed with fuel. The increased volume of air and fuel creates a more potent combustion event, which translates to increased engine power. However, this power boost does come with some additional complexity, as the engine must be able to handle the increased pressure and temperature generated by the turbocharged process.

While the turbocharger does an excellent job of compressing air and forcing more oxygen into the engine, there is a challenge that arises in the process. When air is compressed, it heats up. This increase in temperature can actually reduce the air’s density, limiting the benefits of the turbocharger. This is where the intercooler comes into play. The intercooler is a heat exchanger that cools the compressed air before it enters the engine. By lowering the temperature of the air, the intercooler ensures that the air remains dense, which maximizes the performance benefits of the turbocharger.

Intercoolers come in different forms, with the most common being air-to-air and air-to-water. An air-to-air intercooler works by using ambient air to cool the compressed air, while an air-to-water intercooler uses water as a cooling medium. Both systems are designed to reduce the temperature of the compressed air and enhance the overall efficiency of the turbocharging process.

Turbochargers offer a wide range of benefits, which is why they are used in so many modern vehicles. One of the most obvious advantages is the increase in engine power. By forcing more air into the combustion chamber, a turbocharger allows an engine to produce more power without increasing its physical size. This is particularly important in the automotive industry, where manufacturers are constantly striving to produce more powerful engines that are also fuel-efficient and lightweight.

For performance vehicles, turbochargers enable higher levels of acceleration and top speed without the need for larger, more fuel-hungry engines. A smaller, turbocharged engine can provide the same, or even more, horsepower as a naturally aspirated engine while consuming less fuel. This makes turbochargers especially valuable in sports cars and performance sedans, where the goal is to maximize power while minimizing weight and fuel consumption.

In commercial and industrial vehicles, turbochargers improve fuel efficiency and towing capacity. Trucks and heavy-duty machinery often require more power to haul heavy loads or operate in demanding conditions. A turbocharged engine can provide the additional power needed while still maintaining fuel economy, which is essential for businesses that rely on these vehicles for daily operations.

Additionally, turbochargers help meet environmental regulations. By improving the efficiency of the combustion process, turbochargers enable engines to produce more power while burning less fuel, which leads to fewer emissions. This is increasingly important as governments around the world impose stricter emissions standards on vehicles.

While turbochargers offer numerous advantages, they are not without their challenges. One of the most significant issues is turbo lag, which refers to the delay between pressing the accelerator pedal and the engine’s response. Turbo lag occurs because the turbocharger relies on exhaust gases to spin the turbine and compress the air. When the accelerator is pressed, there is a brief period before the engine produces enough exhaust gases to spool up the turbocharger and deliver the expected power.

Engineers have worked hard to minimize turbo lag by designing smaller, more efficient turbochargers and utilizing advanced technologies such as twin-scroll turbos and variable geometry turbochargers. These systems are designed to improve the response time of the turbocharger, making it more immediate and smoother.

Another challenge is the added stress placed on the engine. Turbochargers operate under extreme conditions, with high temperatures and pressures. This can lead to increased wear and tear on the engine components, particularly if the system is not properly maintained. Regular oil changes and ensuring that the engine is operating within optimal temperature ranges are essential for maintaining the longevity and performance of a turbocharged engine.

The technology behind turbochargers continues to evolve. Engineers are constantly finding new ways to improve the efficiency and performance of turbochargers. One area of innovation is in hybrid turbocharging systems, which combine electric motors with traditional turbine-driven systems. These hybrid systems can reduce turbo lag significantly and improve overall engine responsiveness, creating a smoother and more efficient driving experience.

Another exciting development is the use of variable geometry in turbochargers. In a traditional turbocharger, the turbine blades are fixed at a specific angle, which works best for a narrow range of engine speeds. However, variable geometry turbochargers use adjustable blades that change their angle depending on the engine speed. This allows the turbocharger to optimize performance across a broader range of engine speeds, reducing turbo lag and improving efficiency.

Additionally, advancements in materials science are allowing turbochargers to withstand even higher temperatures and pressures, further improving their durability and performance. Lightweight materials, such as ceramics and advanced alloys, are being used to reduce the overall weight of turbochargers, which is crucial for enhancing fuel efficiency and performance.

Turbochargers represent a remarkable feat of engineering that has transformed the automotive world, providing a way to enhance performance and efficiency without increasing the size of the engine. By harnessing the power of exhaust gases, turbochargers force more air into the engine, enabling it to burn more fuel and produce more power. This has far-reaching implications, from boosting performance in sports cars to improving fuel efficiency in commercial vehicles. As technology continues to advance, turbochargers will likely play an even more critical role in the future of automotive and industrial engineering. Whether it's improving acceleration, reducing emissions, or enhancing towing capacity, turbochargers are undoubtedly here to stay as an essential component of modern engines.